Considering a wood engraving machine for your projects or business? Key features like precision, speed, engraving area, and software integration must be at the forefront of your mind. Our guide cuts through the jargon to assist you in identifying the right machine that meets your specific engraving needs—whether it’s for intricate art pieces or robust production demands.

Key Takeaways

- Wood engraving machines enable precision and intricate design on various wood types and other materials, with factors such as engraving complexity, scale, and laser power settings being crucial for optimal results.

- Essential features to look for in top wood engraving machines include powerful lasers, advanced software compatibility, and versatile material handling, while safety and regular maintenance are key to ensuring longevity and safe operation.

- Investing in a wood engraving machine requires careful consideration of material types, cost versus quality, brand reputation, and the need for additional tools and accessories to enhance woodworking capabilities.

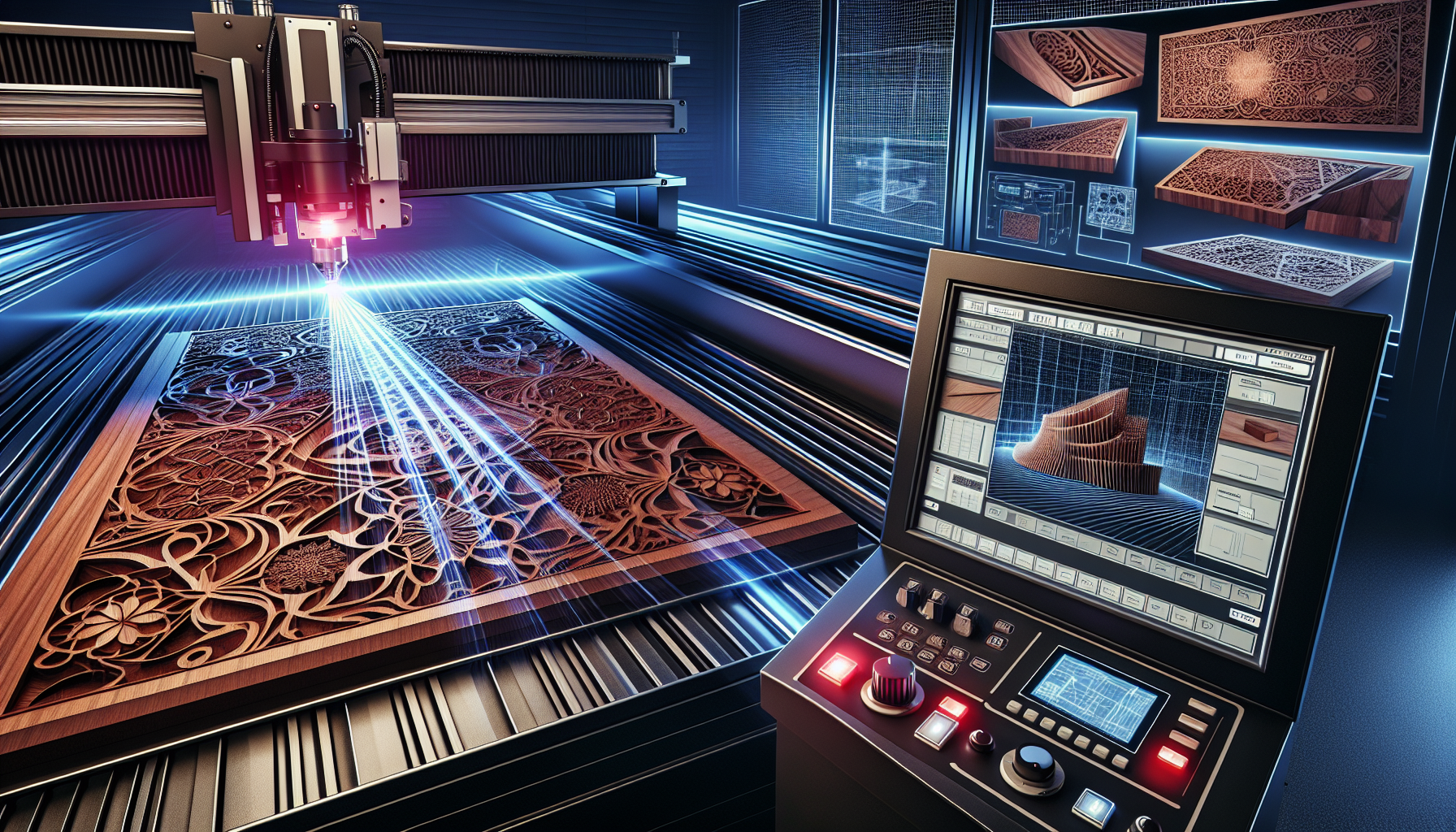

Exploring the Capabilities of Wood Engraving Machines

Gone are the days when woodworkers were confined to the limitations of manual tools. The advent of wood engraving machines has ushered in a new era of possibilities. These specialized devices are adept at carving, etching, or marking various wood surfaces, satisfying the most demanding of design aspirations. From the soft whispers of pine to the stoic resilience of cherry, these machines handle an impressive array of wood types, offering flexibility to artisans across the spectrum of their projects.

Yet, the suitability of a wood engraving machine for a particular endeavor hinges not just on the wood type but also on the complexity of the desired engravings. The scale of projects is another critical consideration – some machines excel in large-format marking, perfect for grand creations that demand a broader canvas.

Precision Cutting and Intricate Designs

Precision is a guaranteed feature with a laser engraving machine. The magnificence of laser technology lies in its ability to achieve high precision and intricate designs unattainable with conventional woodworking methods. Signs adorned with precise and complex details are just one example of the exceptional accuracy that these machines can deliver in a single pass. Companies like MonportLaser take precision to the next level with advanced CO2 engravers, capable of etching custom designs onto wood signs with remarkable accuracy.

Moreover, cutting and shaping functionality is a critical factor when selecting an engraving machine, as it empowers artisans to craft precise shapes for diverse products, from decorative clocks to elegant inlays.

The Power of Laser Engraving on Wood

The effectiveness of laser engraving depends not only on the laser’s power but also on the balance between the laser’s power and speed settings. This balance is paramount for achieving optimal engraving results and accommodating various material thicknesses.

Properly configured laser power settings are instrumental in ensuring laser-cut wood signs are not only aesthetically pleasing but also durable and wear-resistant. The interplay of the appropriate laser speed and power settings significantly amplifies the accuracy and quality of cuts, an advantage that shines in applications like quick prototyping, where time is of the essence.

Essential Features of Top Wood Engraving Machines

A professional wood engraving machine consists of:

- A powerful laser, which allows for precise cutting and versatile material handling

- CAD/CAM systems and digital controllers, such as the RUIDA, which bring about a level of precision cutting and adjustments

- The marriage of these components opens up a realm of complex project possibilities, propels efficiency in prototyping, and amplifies user control over the engraving process.

This versatility is what positions top wood engraving machines as an indispensable asset in the woodworking toolbox., as they’re designed to handle not just wood but an array of other materials, widening the horizons for professional applications.

Software Integration and Ease of Use

In the realm of laser engraving, software takes the lead, providing the control over design and cutting processes needed to transform creative ideas into reality. Machines from brands like Trotec boast broad software compatibility, interfacing seamlessly with a multitude of illustration and photo-processing programs, as well as specialized CAD & 3D Design software, supporting a wide array of file formats to cater to diverse user needs. Software solutions like Trotec’s JobControl and SpeedMark extend the capabilities of flatbed and galvo laser systems, respectively, enabling list outputs from standard office or graphics software and even creating consecutive numbering for codes and serial numbers.

For those just dipping their toes into the laser engraving waters, user-friendly and free software options such as Inkscape are available, with compatibility checks for CNC machine controllers like Lightburn or Vectric ensuring a seamless workflow.

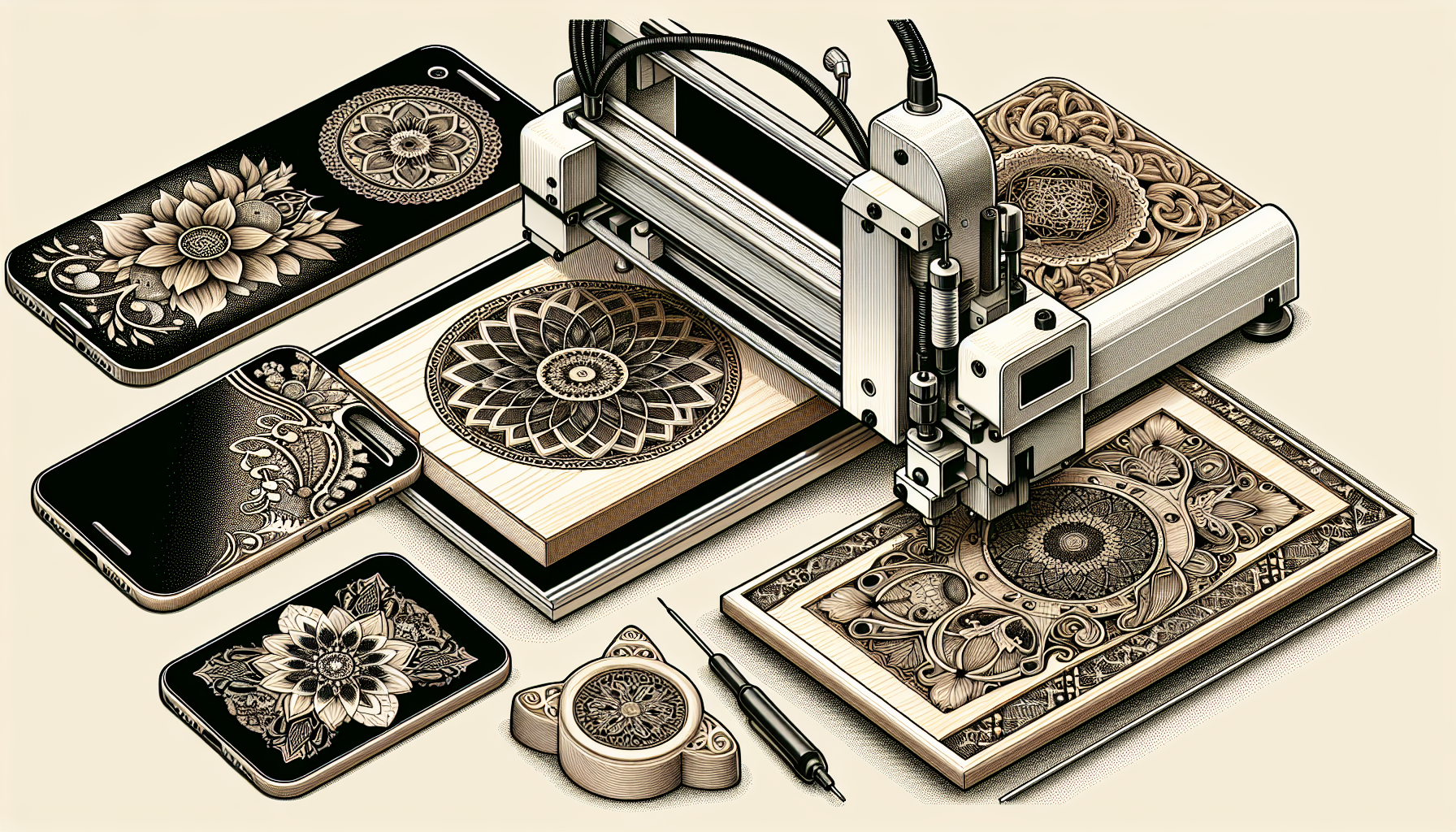

Material Versatility: Beyond Just Wood

While wood is an obvious material for these machines, it’s just the starting point in the extensive list of materials that wood engraving machines can master. These machines demonstrate their prowess by precisely handling materials like MDF and plywood, broadening the versatility of projects and the scope of artisanal creation. For craft businesses looking to expand their horizons, the machines’ utility in mixed media art and image transfer applications is a game-changer, enabling them to venture into new creative territories.

And it’s not just about wood – laser engraving can etch enduring and resistant custom designs onto phone cases made from varied materials, including plastic and leather, adding a personal touch to everyday objects. With machines like the LONGER Ray5 10W, artisans can leave their mark on a diverse range of materials, from wood to acrylic, thereby enhancing their craft business’s product offerings.

Personalizing Your Creations with Engraving

Wood engraving machines offer limitless possibilities in the art of personalization. These machines can turn a simple skateboard, phone case, or guitar into a bespoke masterpiece, infusing each item with a unique character that sets it apart. The laser engraving technology available today elevates the personalization of wood products, enabling the creation of high-quality designs that add a distinctive touch to any space, be it through elegant mahogany picture frames or natural pine phone cases with photo engravings.

The choice of material is key, and with a variety of options at hand, these machines cater to intricate designs and the highest quality expectations.

From DIY Enthusiasts to Professional Artisans

Wood engraving machines cater to both seasoned professionals and DIY enthusiasts, becoming an essential tool in both circles. They enable the creation of intricate items such as inlays for cabinets, awards, and even guitars, adding significant value to various woodworking projects. DIY enthusiasts leverage these machines to produce unique and personalized items, enhancing the appeal and value of their homemade products. For hobbyists, the allure lies in machines that are versatile, easy to use, and require no complex assembly, supporting the growth of their creative endeavors.

On the other hand, there are laser engraving machines designed specifically for professional artisans, focusing on high-speed and detailed engraving capabilities to meet the rigorous demands of commercial production. But whether for a hobbyist or a professional, the ability of these machines to laser engrave on various materials opens up a vast landscape of creative possibilities. Some of the materials that can be engraved include:

- Acrylic

- Leather

- Paper

- Aluminum

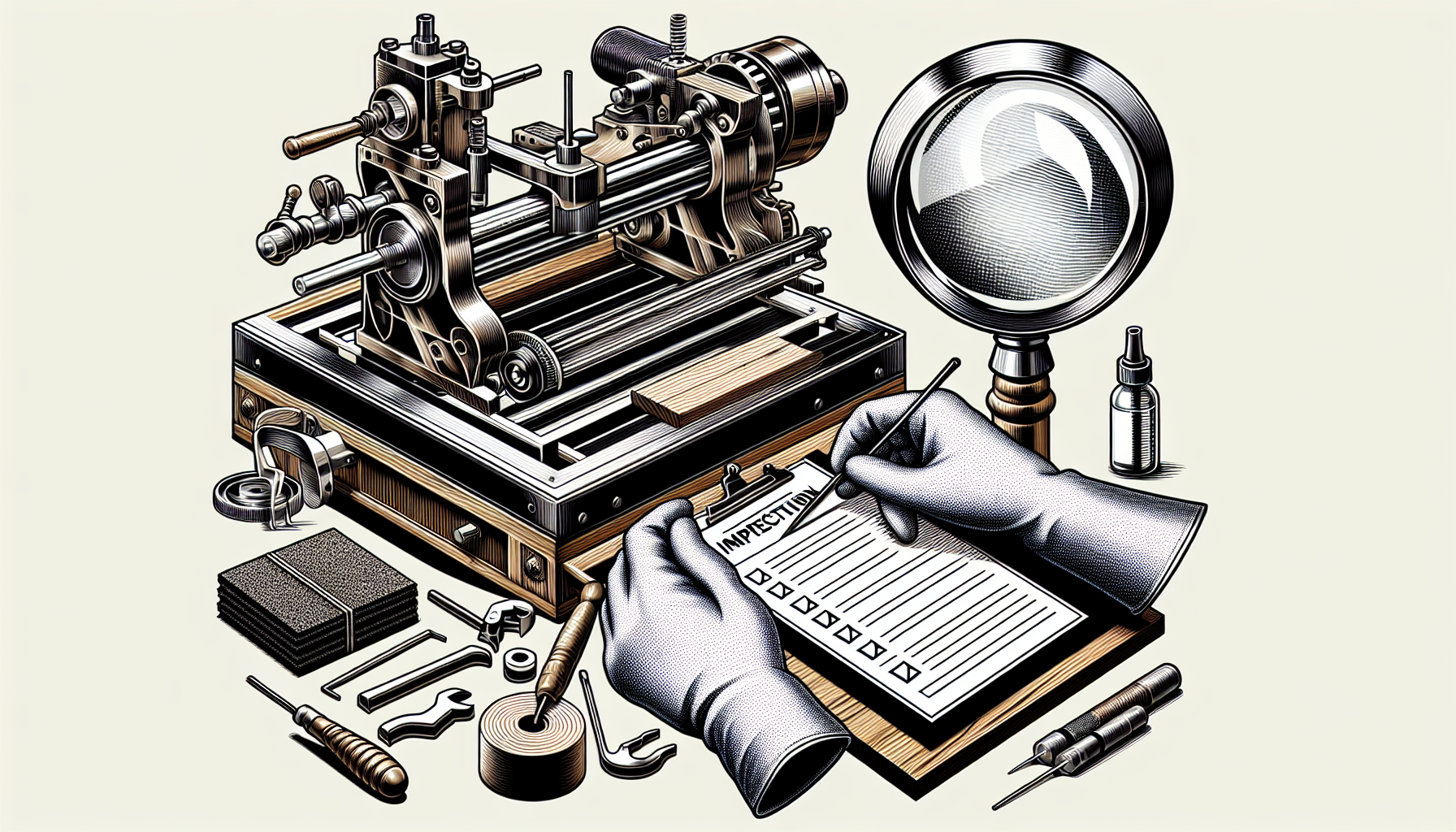

Safety and Maintenance of Your Engraving Machine

Responsible operation of laser engraving machines strongly depends on safety and maintenance., which are categorized within a classification system from Class 1 to Class 4. Class 4 machines, in particular, demand extra caution due to the higher risks of skin injuries and fire hazards.

Regular maintenance is not only crucial for the longevity of the machine but also for ensuring a safe working environment, whether it’s a small DIY workshop or a large commercial space. Some key maintenance tasks that cannot be overlooked include:

- Keeping the machine and its surroundings clean

- Checking and cleaning optics

- Lubricating moving parts

- Inspecting air filters

By performing these tasks regularly, you can ensure that your machine is in optimal condition and reduce the risk of accidents or breakdowns.

Preventive Measures to Avoid Accidents

Accidents in the workshop can be catastrophic, but they are preventable with the right measures in place. Protective measures, such as enclosures around the laser path and interlocks on removable guards, are critical for preventing skin burns and laser-related fires. Regular maintenance of a laser engraver’s electrical and pneumatic systems, including the laser head, is not to be underestimated, as it is vital to minimize the risk of electrocution or explosions. Fume extraction systems are another essential component, removing dangerous fumes and particles produced during the engraving process, with HEPA filters playing a pivotal role in capturing emissions in environments lacking direct outside ventilation.

Moreover, having a Laser Safety Officer (LSO) to oversee laser safety protocols, operation, training, and adherence to safety standards can be instrumental in maintaining a secure environment.

Keeping Your Machine in Top Condition

The adage “prevention is better than cure” holds true for the maintenance of laser engraving machines. Regularly cleaning the machine of contaminants like smoke, resin, and dust is imperative to prevent accidents and ensure smooth operation. Optical components are the eyes of the machine, and keeping them clean is essential for maintaining engraving quality. Additionally, checking the ventilation system to prevent obstructions is crucial for preserving machine efficiency. A solid ground line wire is also necessary to prevent electrostatic interference during the engraving process, so regular checks are a must.

Lastly, for those using CO2 laser tubes, maintaining a constant temperature for the cooling water with water chillers extends the life and performance of the laser tube.

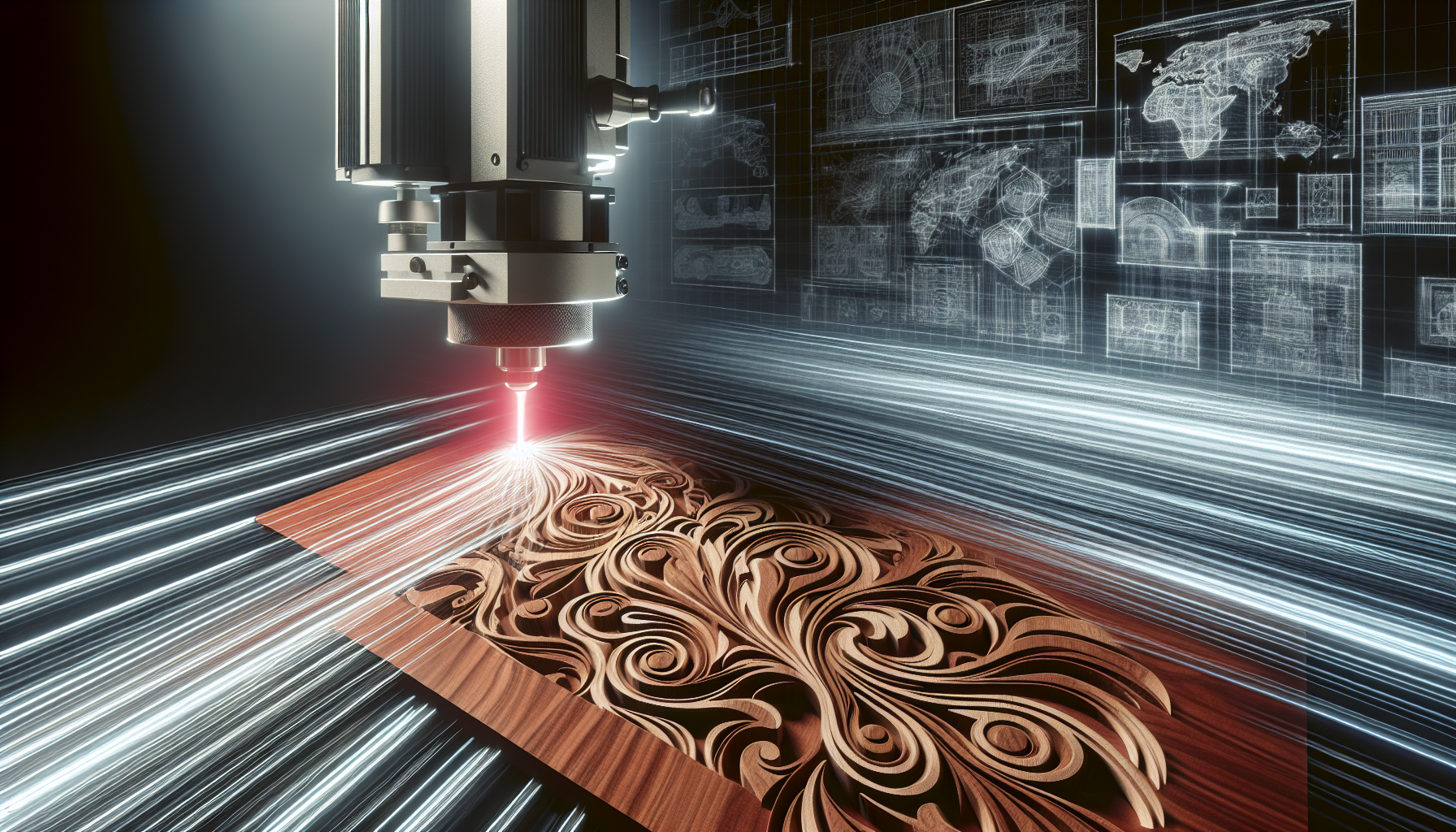

Maximizing Productivity with Efficient Wood Cutting

Laser engraving technology plays a significant role in maximizing productivity through efficiency. With the power to accelerate the wood laser cutting process, laser systems enable quicker project completion, eclipsing traditional cutting methods. Whether working on commonly used materials like MDF and plywood or experimenting with new substrates, a laser system can expedite the workflow for wood prototyping considerably, reducing the time from conception to completion.

Blue diode laser engravers are particularly praised for their speed in wood cutting, thanks to their high electrical efficiency and the material’s good absorption of the laser. Moreover, the application of a laser system not only quickens the creation process from prototyping but also lessens the downtime between design iterations.

Speed and Efficiency in the Engraving Process

The speed of a laser engraver is a determining factor in how swiftly it moves across the material on the workbed, impacting the overall time taken for the engraving process.

Some considerations for laser engraving speed are:

- Large, less detailed projects benefit from faster laser engraving speeds

- Intricate designs necessitate slower speeds to maintain detail and quality

- If the laser moves too quickly, it may not engrave deeply enough or could skip parts of the design

- Moving too slowly risks burning the material

The LONGER Ray5 10W, with its high engraving speeds and dual beam technology, demonstrates how efficiency and rapid production can increase output and save time.

Leveraging Laser Precision for Quick Prototyping

Laser cutting offers:

- High-quality finishes

- Adaptable production capacities

- Effectiveness for single prototype parts and large batches without retooling

- Precision for intricate designs

- Facilitation of rapid prototyping across various materials

- Streamlining the transition from concept to tangible prototypes.

Rapid prototyping via laser engraving machines significantly reduces development time, allowing for swift responses to design changes and refining the path from idea to final product.

Investing in a Wood Engraving Machine

Investing in a wood engraving machine, whether you’re an experienced woodworker or a beginner, is a pivotal decision that can shape the course of your craft. The material you plan to engrave on is a determining factor in selecting the suitable type of machine, with considerations such as engraving area size and the machine’s ability to integrate with various CNC machines being paramount.

Different materials may also necessitate different laser wavelengths, optical powers, or power densities, as well as consideration of the material’s optical properties like color, tint, and shade.

Cost vs. Quality: Finding the Right Balance

The cost of a wood engraving machine is often an indicator of its capabilities, such as:

- power

- precision

- versatility

- expected durability and lifetime

While a more expensive machine may seem like a hefty initial investment, it can lead to increased productivity and profitability over time, providing a better long-term return on investment.

The price of industrial laser engraving machines varies based on a range of factors, including the engraving area, component quality and durability, and the laser’s power. Additionally, high electricity consumption due to poor electrical-to-optical power conversion can be a hidden cost factor for some machines.

Choosing a Reputable Brand

Selecting a reputable brand for your wood engraving machine is critical, as it often guarantees comprehensive warranties and service packages, providing protection against equipment malfunctions and breakdowns. The choice of a wood engraving machine brand should consider the significant investment and space required, especially for machines with large working areas and high power. However, it’s essential not to be swayed solely by the brand name, as innovation and efficiency offered by smaller, newer companies can sometimes surpass that of established brands.

Evaluating performance and power consumption is crucial, as reputable brands may not always be the best choice for everyone’s specific needs.

Enhancing Your Woodworking Toolbox

Advancing in woodworking generally requires the addition of new tools and skills to your repertoire. Some essential tools for woodworking include:

- Cordless drill: a versatile tool that allows for easy drilling and driving screws. An extra battery is useful for continuous work on larger projects.

- Hex drivers and drills with magnetic holders: these tools streamline the bit changing process, making it quick and efficient.

- High-quality bits made of hardened steel: these bits are recommended for their durability and reduced risk of breakage.

By adding these tools to your collection, you can enhance your woodworking skills and take on more complex projects.

Magnetic screwdrivers also play a vital role in precision tasks, where their strong magnets help keep steel screws secure and provide additional magnification.

Must-Have Accessories for Laser Engraving

The right accessories can add versatility to your wood engraving project. Rotary attachments, for instance, are indispensable for engraving curved objects like bottles and glasses, allowing the laser machine to adapt to a variety of shapes. For engraving taller materials, risers can be used to increase the height within the laser machine, which can be especially useful when working with rotary attachments for items such as bottles.

Different focus lenses are also pivotal for handling various material thicknesses and achieving precise details, from cutting softer materials to creating fine text. Additionally, an air assist kit can significantly enhance the performance of laser engravers like the LONGER Ray5 10W, contributing to the creation of complex, high-quality designs.

Expanding Your Craft with Additional Modules

Incorporating various modules and tools can further expand your craft and enhance your woodworking projects. A height adjustment tool, for example, is a must-have accessory for laser engravers and cutters, ensuring precision across various material heights. Expansion kits, such as the SCULPFUN S9 410 x 950mm Large Area Expansion Kit, significantly increase the working area of your laser engraver, allowing you to undertake large projects like tables or doors. These modules are designed to be user-friendly, with quick assembly times of 10-20 minutes, enabling easy upgrades and increased engraving capabilities. The extension shafts and cables provided in these kits are rigorously tested to maintain precision and stability, ensuring that the expanded engraving machine performs as well as the standard setup. Moreover, these additional modules often come with all necessary accessories included, eliminating the need for extra purchases.

Summary

In the intricate dance of woodworking, a wood engraving machine is a partner that leads with precision, versatility, and creativity. From exploring the vast capabilities and essential features to mastering personalization, safety, and maintenance, wood engraving machines stand as pillars of modern craftsmanship. Efficiency in cutting, judicious investment, and enhancing the woodworking toolbox with accessories and modules round out the journey to mastery. Whether you’re a DIY enthusiast or a professional artisan, the world of wood engraving awaits – a world where every piece of wood is a canvas for your imagination.

Frequently Asked Questions

What is the difference between CNC and laser engraver for wood?

The main difference between a CNC and a laser engraver for wood lies in their methods of engraving. A laser engraver uses a high-energy laser to cut and engrave the wood, while a CNC engraver utilizes a high-speed rotating cutter head to achieve the same result. This leads to a distinct variance in the action applied to the material.

How much does an engraving machine cost?

An affordable fiber laser engraving machine costs around $5,060, while a budget-friendly CO2 laser engraving machine averages about $3,680. These are the average prices as of 2024.

What is the best way to engrave wood?

The best way to engrave wood at home is to use traditional hand tools like chisels and gouges, or a modern approach with a compact desktop laser cutter for precision. Both methods offer different advantages for wood engraving.

What is best machine for engraving wood?

The most suitable machines for engraving wood are CO2 and diode laser machines because they are powerful and efficient. CO2 machines take less time, while powerful diode lasers can also engrave at a fast speed.

What types of wood can laser engraving machines handle?

Laser engraving machines can handle a variety of wood types, including softer woods like pine and denser hardwoods like cherry, providing flexibility in project selection and design intricacy.