If you’re exploring the fine craft of wood laser engraving, this article is your definitive guide. Here, we break down the selection of woods ideal for detailed engravings, precise settings for your laser machine, and the pathway to perfection in your finished pieces. Delve into practical advice and inspiring project examples, all focused on helping you excel at this artisan skill without the fluff.

Key Takeaways

- Wood laser engraving allows for intricate designs on a variety of wooden objects, from custom artwork and furniture patterns to personalized items and business branding, using advanced machines capable of detailed and 3D engravings.

- Selecting appropriate wood types and preparing the material by sanding and cleaning are essential for achieving optimal results in laser engraving; adjusting laser power and speed settings is crucial for the depth and clarity of engravings.

- Laser cutting technology enhances woodworking by offering precise cutting capabilities and efficiency, which are particularly beneficial for rapid prototyping and production of complex geometries.

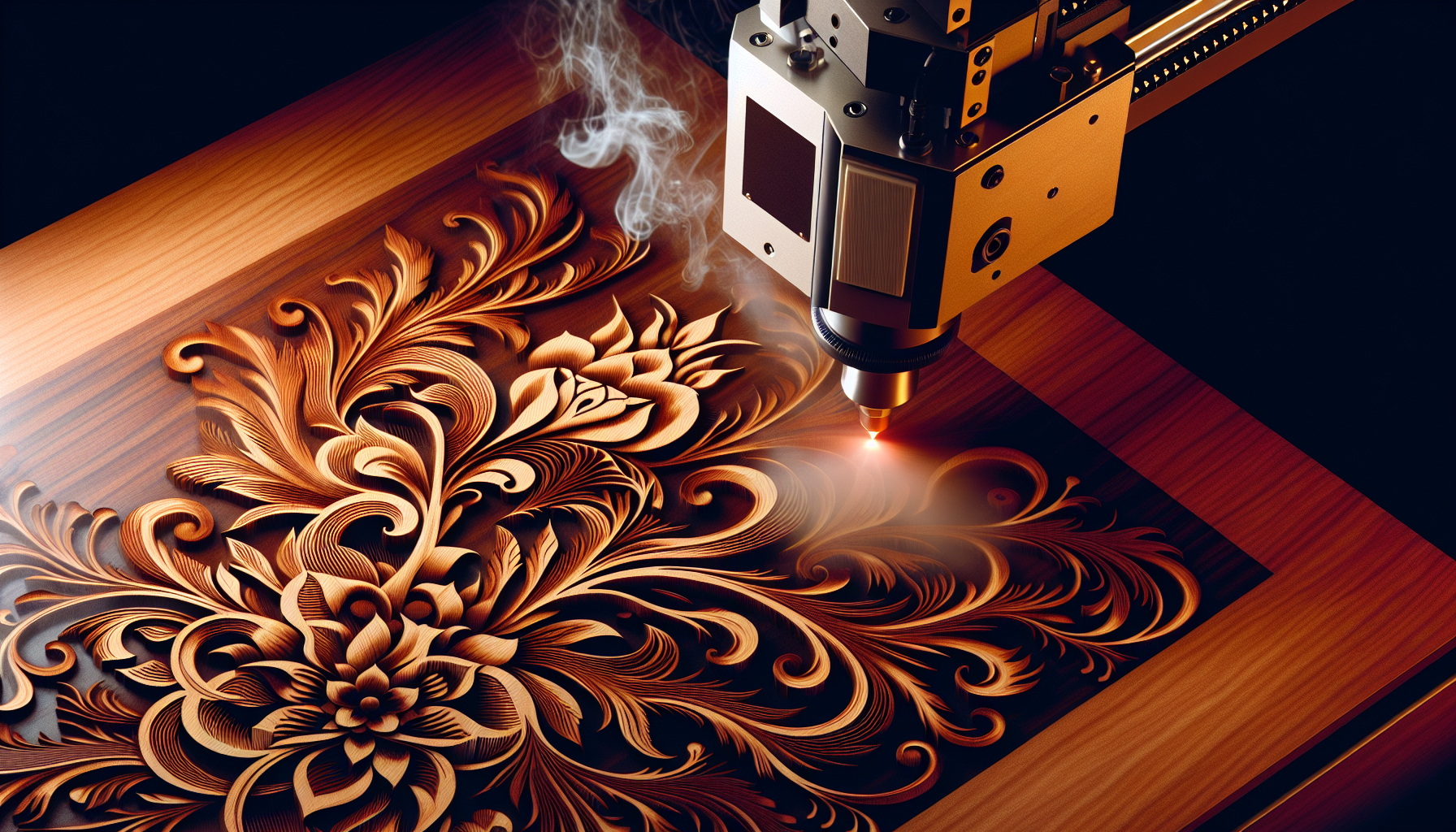

The Art of Wood Laser Engraving

Laser engraving on wood is like painting with a beam of light. Each stroke of the laser beam carves out intricate designs, burning and vaporizing the material. It is the intricacy of design that impacts the engraving process, requiring slower movement for detailed patterns, and thus increasing the time of the engraving process. This art form is not restricted to two dimensions either. With advanced laser engraving machines like Kern’s, known for its 3D engraving technology, the possibilities are nearly endless.

Laser cutting has revolutionized woodworking by allowing for more complex and precise designs than traditional cutting methods. With the aid of a laser engraver, artists can create:

- Custom artwork

- Intricate designs

- Detailed patterns on furniture

- Personalized engravings on small wooden items

Laser engraving brings a whole new level of customization to woodworking projects.

The Basics

At the heart of the laser engraving process is the laser head, which focuses and directs the laser beam with high precision. This concentrated beam of light can engrave detailed designs into wood surfaces at speeds as fast as 4000 mm/s, although the speed may vary based on the specific model and configuration of the laser engraving machine.

The laser head’s precision and the control over engraving speed are critical to achieving fine details and intricate designs in the final product.

Suitable Wood Types

Choosing the right wood type is crucial for laser engraving as it affects the quality, appearance, and ease of engraving, ultimately impacting the final outcome of the laser engraved product. Oak, birch, maple, and basswood are among the suitable woods for detailed laser engraving. For instance, basswood is preferred for its softness, light color, and smooth surface that result in high-visibility engravings. Other options include walnut for its smooth surface and dark color, bamboo for its durability and consistent grain, and maple for its hard and dense characteristics, ideal for accurate engravings.

Customizing Wooden Items with Laser Engraving

Laser engraving is not just about creating art; it’s also about personalizing items and enhancing their aesthetic appeal. With the help of a laser engraving machine, you can transform a variety of wood items, such as furniture, picture frames, and cutting boards, into personalized works of art. Whether it’s a decorative design or lettering, laser engraving can significantly enhance the items like furniture, floors, musical instruments, and other decorative pieces.

In addition to enhancing the aesthetics, laser engraving also offers a unique opportunity for personalization and branding. You can add a personal touch to gifts or strengthen your business branding by engraving logos or other branding elements onto wooden items. From intricate designs on a cutting board to a company logo on a set of coasters, laser engraving adds a level of personalization that truly sets these items apart.

Personalized Gifts

Laser engraving on wood enhances items by adding custom artwork and personalized touches, transforming ordinary objects into unique gifts. A variety of wooden items, including cutting boards, picture frames, and jewelry boxes, can be personalized using laser engraving technology.

Customized wooden serving platters, utensils, and photo-engraved items serve as rustic and thoughtful gifts. For instance, wooden cutting boards are particularly fitting for 5th-anniversary presents, aligning with the tradition of giving wooden gifts.

Business Branding

Laser engraving is an effective tool for strengthening business branding. By engraving company logos on wooden items, businesses can create a lasting impression. The precision of lasers makes them ideal for creating detailed and accurate representations of company logos on wooden promotional materials.

Whether it’s mass-producing personalized items like corporate giveaways or creating custom merchandise, laser engraving allows businesses to showcase their brand in a unique and tangible way.

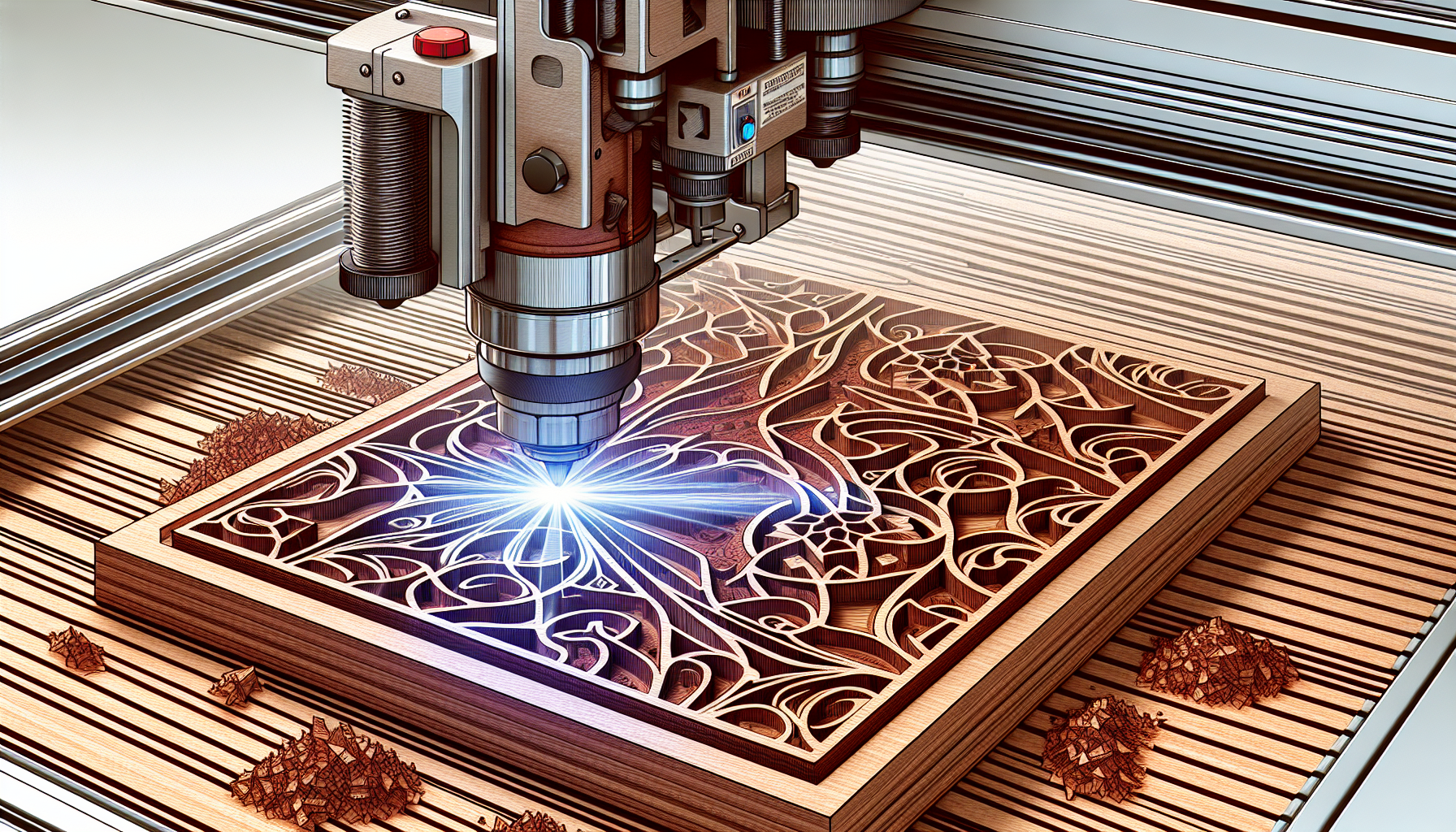

Enhancing Woodworking Projects with Laser Cutting

Laser cutting has brought a new level of precision and efficiency to woodworking. With the ability to cut various types of wood, including harder and thicker materials, wood laser cutting allows a broader range of woodworking projects to be enhanced, from cabinetry to photo frames. The focused intensity of laser beams creates precise, clean cut edges, often reducing or eliminating the need for additional finishing steps.

Modern laser cutting machines are not only precise but also cost-efficient, leading to high yields of material with minimal waste. This efficiency, combined with the precision of the cut, has revolutionized the production of high-quality wood products, transforming the woodworking industry.

Rapid Prototyping

The use of laser cutting technology in prototyping is changing the game by allowing for the creation of prototypes that are accurate representations of the intended final product. Laser cutting offers several advantages for rapid prototyping:

- Cost-effective alternative to traditional sawing or milling

- Quicker turnaround for prototypes

- Ability to produce shapes with precise measurements

- Savings in time and material usage

Whether it’s a simple design or an intricate pattern, laser cutting is a valuable tool for creating high-quality prototypes.

The precision of laser cutting allows for the creation of woodworking components with complex geometries that might be too costly to produce with traditional subtractive machining.

Precision and Complexity

High-precision laser engraving enables the creation of complex shapes and intricate designs, transforming the possibilities in woodworking projects. Some benefits of laser engraving in woodworking include:

- Adding depth and texture to designs

- Enhancing the visual complexity of wood projects

- Creating intricate patterns and details

- Engraving logos or personalized messages

- Achieving precise and consistent results

With wood engraving, woodworkers can take their projects to the next level by laser engraving wood, creating unique and stunning pieces using wood laser cutters.

In addition, the engraving speed of the laser impacts how quickly the laser moves across the material, affecting both the processing time and the depth of the cuts, which is crucial for detailing.

Tips for Perfect Wood Laser Engraving

Mastering the art of laser engraving on wood requires understanding the material and the machine. One of the crucial steps is to prepare the wood properly, which includes sanding, cleaning, and selecting the right wood type. Sealing wood before laser engraving can prevent burn marks and resin seepage, enhancing the quality and durability of the final product.

Another key aspect is adjusting the laser power and speed. Achieving darker engravings on wood significantly enhances the contrast and visibility of the design, making detailed engravings more prominent. However, it’s advisable to test darkening methods on a small wood sample to ensure the desired effect is achieved without compromising the intricacy of the engraving.

Preparing the Wood

Before you start engraving, it’s important to prepare the wood properly. This includes sanding the wood to a smooth finish, which ensures that imperfections do not interfere with the accuracy of the laser engraving. You can also conduct tests on scrap pieces of wood to determine the optimal laser settings, which is important for the preparation phase.

Finally, selecting the right wood type is essential for achieving the desired effects in laser engraving, especially when working with the same wood.

Adjusting Laser Power and Speed

The power and speed settings on laser engravers must be calibrated depending on the type of wood and the complexity of the design to achieve optimal engraving results. The power of the laser, usually measured in watts, influences the depth and darkness of the engraving when adjusted in conjunction with engraving speed. However, it is recommended to test the laser on a scrap piece of wood to fine-tune the settings before executing the final engraving, ensuring the desired outcome.

The quality of the engraved edges, being smooth or rough, serves as an indicator of whether the laser power and speed settings are adjusted properly for the wood in use.

Preventing Burn Marks

One of the common challenges in laser engraving is preventing burn marks. This can be achieved by proper preparation of the wood, which includes sanding, cleaning, and applying a light finish. Some woods may require the use of masking or a sacrificial layer during engraving to protect the surface from burn marks.

By taking these preventative steps, you can achieve a clean and high-quality finish in your laser engraving projects.

Software for Wood Laser Engraving

Choosing the right software is crucial for achieving high-quality results in wood laser pictures engraving as it converts designs into a format readable by the laser machine and allows control over the engraving process. There are several software options available for wood laser engraving projects, including:

- CorelDRAW

- Adobe Illustrator

- Photoshop

- ArtCAM

- Cimigrafi

When deciding on an engraving software, it is essential to consider its ability to handle the desired intricacy of work, compatibility with the laser engraver, and the specific design tools it offers for engraving tasks. For instance, vector graphic design in Adobe Illustrator enables precise control and the ability to create complex designs for laser engraving.

Creative Ideas for Wood Laser Engraving Projects

If you’re looking for some creative project ideas for wood laser engraving, look no further. Laser engraving can transform everyday functional items into personalized works of art, providing both utility and aesthetic appeal. Here are some ideas to get you started:

- Personalized wooden keychains that can showcase individual interests or a child’s drawing

- Personalized wooden clocks

- Engraved wooden cutting boards

- Customized wooden coasters

- Engraved wooden photo frames

- Personalized wooden signs

- Customized wooden phone cases

The possibilities are endless!

In addition to personal items, you can also transform your home decor with laser engraving. Whether it’s wooden wall art engraved with personalized imagery or intricate patterns, or functional items like clocks and coasters enhanced with laser engraving, you can add a personal touch and elegance to your everyday objects.

Artistic Wall Hangings

Wooden wall art can be laser-engraved with personalized imagery or intricate patterns, making them suitable for customized home decor. Some ideas for innovative wall art include:

- Laser engraving intricate designs like snowflakes or family trees onto wood

- Creating personalized wall art with names or quotes

- Engraving images of animals or nature onto wooden panels

These unique and customized pieces can add a personal touch to any room in your home.

Even simple wooden panels can be transformed into wall art with elaborate laser-engraved patterns, adding depth and warmth to your home decor. With laser engraving, you can truly make your home decor unique and personal.

Functional Items

Functional items such as clocks, coasters, and phone cases can be transformed into personalized pieces with laser engraving. Materials like bamboo can also be effectively laser-engraved to create decorative and playful characters or figures. Even coasters made from premium woods not only serve the practical purpose of protecting surfaces but can be made elegant through precise laser engraving.

With laser engraving, everyday objects can become artistic expressions.

Summary

In conclusion, laser engraving has revolutionized woodworking, offering unprecedented precision and customization options. From selecting the right wood type and preparing it properly to adjusting the laser power and speed, mastering laser engraving requires understanding both the material and the machine. With the right software and creative ideas, you can transform everyday items into personalized works of art or enhance your business branding. Why not explore the world of laser engraving and discover what you can create?

Frequently Asked Questions

Can you laser engrave wood?

Yes, wood can be laser engraved using a suitable lens based on the material thickness. It is a commonly used material for laser engraving due to its affordability and visual appeal.

How much does a good laser engraver cost?

A good laser engraver can cost between $1500 to $2500, but prices may vary based on features, brand, and seller, so it’s important to check the latest prices and reviews before purchasing.

What is a good laser engraver for wood?

I recommend comparing these 5 machines for wood engraving to find a good laser engraver. Consider factors such as power, precision, and user reviews to make an informed decision.

What is laser engraving and how does it work?

Laser engraving is a method that uses a concentrated beam of light to create designs on materials like wood by burning and vaporizing the material, resulting in precise and intricate designs. This process is highly effective for customization and artistic applications.

Which wood types are suitable for laser engraving?

Oak, birch, maple, basswood, walnut, and bamboo are suitable for detailed laser engraving due to their distinct characteristics that affect the final outcome.